When you need accurate insight into the size, volume, depth, and extent of a dry void there’s only one survey that can provide it: a subsurface laser scan survey. That’s exactly what Geoterra specialises in.

We carry out subsurface laser scan surveys of dry cavities across the UK and Ireland. Our surveys capture precise, georeferenced 3D data of underground voids that are difficult to access and cannot be fully mapped using other survey techniques.

Whether you’re dealing with old mine shafts, collapsed tunnels, or undocumented structural voids, our subsurface laser scan surveys provide you with the information you need to make informed decisions before any remediation or site work begins, and public access is granted.

With this survey, you get a complete picture of the discovered void. This helps you to reduce risk, plan remediation works and manage complex underground voids efficiently and with confidence.

Need expert advice on surveying a dry cavity?

Contact our team to discuss the best approach for your site.

What is a subsurface laser scan survey of a dry void?

A dry cavity is an underground, air-filled void with no water present. These can be naturally formed, like limestone karst systems, or manmade, such as mine workings, culverts, or disused tunnels.

You might only discover a dry cavity when:

- The ground collapses or a sinkhole appears.

- Deep excavation or piling work uncovers a void.

- Infrastructure, like roads, railways, or buildings, shows signs of movement or instability.

That’s when we’re called in.

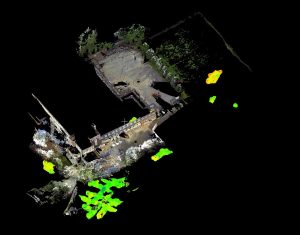

A subsurface laser scan survey maps the void in detail using a specialist laser scanner lowered into a lined borehole. The scanner captures highly accurate, georeferenced 3D data, showing the cavity’s size, depth, volume, and extent. Because the data is georeferenced, you know exactly where the void sits in relation to the surface and surrounding structures.

This gives you a complete picture so you can plan safely, control costs, and manage your project efficiently.

Range of applications

We use subsurface laser scanning to survey many types of dry cavities, including:

- Natural voids – Created by natural processes, often in limestone karst systems.

- Old mine workings – Abandoned or collapsed tunnels, shafts, and chambers from past mining.

- Mine shafts/tunnels – Vertical or horizontal excavations from past or current mining.

- Adits – Horizontal mine entrances, often used for drainage or access.

- Building cellars – Underground chambers below buildings, sometimes undocumented.

- Culverts – Underground drainage channels that can weaken or collapse over time.

- Historical tunnels – Disused or unrecorded tunnels, sometimes linked to transport.

- Structural voids – Hollow areas under bridges, foundations, or other structures.

- Sinkholes (dry stage) – Early voids forming before water enters.

- Dene holes – Vertical shafts dug into chalk, often found in southeast England.

Want to see how we’ve handled similar projects?

View our case studies to see real examples.

How do we survey dry voids?

We use the C-ALS (Cavity Auto-Scanning Laser System) to survey dry cavities. Lowered down a borehole, which is lined to the top of the void, it maps the void in detail and with precision. Key capabilities of the C-ALS include:

- Surveys cavities up to 90 m below ground.

- Scans spaces up to 100 m in length or radius from the borehole entry.

- Captures measurements with ±2 cm resolution and ±3 cm accuracy.

- Operates through a 95 mm internal diameter lined borehole, which must extend to the top of the cavity, making it suitable even for narrow access points.

If, however, you need a denser point cloud, we use a mobile mapping system such as the GeoSLAM ZEB Horizon RT Mobile Scanner or GeoSLAM Revo RT Mobile Scanner. They can be lowered into a dry cavity, but only through a larger access point, such as a shaft. A denser point cloud will provide you with even more detail, a higher level of accuracy, and better surface definition.

We can also use the Leica RTC360 scanner by inverting and lowering into voids and structures to carry out detailed laser scan surveys. It can be lowered up to 8 m below ground level and scan up to 100 m in any direction.

The Leica RTC360 scanner is what we also use to capture the surface. By combining surface and subsurface data, we provide you with a clear understanding of the cavity’s size, volume, depth, and extent relative to above-ground features.

Have an urgent project?

We can deploy a team quickly to site to deliver fast, accurate survey data in emergency scenarios. Request a quote today.

Why subsurface laser scan surveys outperform other methods

Other survey methods, such as Ground Penetrating Radar (GPR) and geophysical surveys, are often the first types of surveys carried out on dry cavities. While they can provide some useful information, these survey types have two key limitations:

- They don’t provide enough detailed information about the cavity, such as size, volume, depth, or extent.

- They are limited in the depths they can reach.

Most mine workings, for example, are up to ~15 – 30 m deep, beyond the reach of these methods:

- Ground Penetrating Radar (GPR) – Effective for shallow cavities (up to ~3 m) but cannot fully map the void.

- Geophysics – Can reach depths up to ~15 m, depending on ground conditions, but results may be inconclusive.

We’re often called in after these surveys when a detailed 3D assessment is needed. With a subsurface laser scan survey, we can reach depths up to ~90 m and provide a full 3D georeferenced model of the cavity, showing the size, volume, depth, and extent to support informed remediation decisions.

Survey data we can deliver

Once a survey is complete, we can provide you with a range of deliverables:

- Georeferenced 3D point cloud and mesh models.

- High-resolution video (black/white or infrared) from within the void.

- Volume calculations for accurate fill/grouting estimates.

- Plans, sections, and visualisations.

This data removes any guesswork, helping you to reduce risks, control costs, and manage safety.

Why this information matters

Every year, sinkholes, shaft collapses, and ground failures occur, putting buildings, infrastructure, and people at risk. In urgent situations, we’re often called to site quickly to deliver the information you need, fast.

Not investigating a dry cavity fully can lead to:

- Unexpected ground collapses beneath critical infrastructure.

- Costly overruns from underestimating grout fill volumes.

- Project delays while waiting for risk assessments.

- Unsafe conditions for contractors and the public.

Survey data also helps you to plan remediation works, including:

- Filling or stabilising voids to prevent collapse.

- Repairing or reinforcing structures affected by underground cavities.

- Making the area safe for construction, infrastructure, or public use.

With our subsurface laser scan surveys, you get comprehensive, accurate, and timely information exactly when you need it most.

Ready to survey a dry cavity?

Call us on +44 (0) 1606 659 019 to discuss your project.

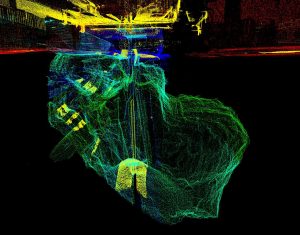

Looking to survey a submerged void?

If your project involves water-filled voids, look at our Subsurface Laser Scan Surveys of Submerged Voids service to see how we can help.